Why Buy A Hyde Drift Boat

Everyone has an opinion. At Hyde we’ve built our opinion on a foundation of sound engineering, proven technology, and performance. Are the people you talk to also basing their opinions on such solid ground? In this report, you will see, not all boats are created equal! We invite you to compare our boats to all other manufacturers. We are confident that you will see why so many people choose Hyde for their river adventures.

At Hyde, we believe that HONESTY and INTEGRITY are THE BEST POLICIES. We’ve built a business on proven technology and solid engineering. Our sales team is committed to selling you the boat you want and need. They will never use sales gimmicks or ploys to sell a boat. Tell us what you want, where you’ll be floating, and what the features the boat needs to have, and they will make it happen!

Hyde is the Industry Leader in drift boat value, innovation, and design. All of our drift boat designs have been tested extensively by three independent engineering colleges to ensure you are getting the product you expect and desire.

From the resin used in the fiberglass to the drain plugs in the back, every aspect of our drift boats has been carefully thought out to give you the best performing boat on the market. Hyde is one of the oldest drift boat manufacturers in the industry. We invite you to compare us to the others and see what sets us a step above the rest

We Test Them

We Build Them

We Use Them

Our Boats

We use only the highest quality products, but equally as important, the most refined craftsmanship to build our boats. Also, unlike much of our competition, we manufacture our own boats. They are crafted in our state-of-the-art production factory in Idaho Falls, Idaho. This means there is no middleman to add to the cost of your boat. This enables us to offer the highest quality at a price nobody in the market can compete with.

Quality is always worth the investment. In the case of our drift boats, we build them to such a high standard because we intend them to last. This means they will hold their value, making your decision to purchase a Hyde boat a good investment. We’re so confident in the quality of our boats that we offer a lifetime warranty on all models; even the reconditioned used ones!

Also, because we build our own boats and most of our accessories, we have complete control of the quality from start to finish. Other boat companies can’t make that same statement.When comparing our boats to other boats on the market, be sure to compare apples to apples. When purchasing a car, you wouldn’t compare Mercedes to Kia. Neither should you make such a comparison when considering drift boats. Our Contender model might be

the best one to compare to others boats. Our other series of boats, quite frankly, have nothing comparable on the market today.

We’ve been building boats for 4 generations now, and we’re confident that will show when you row one for yourself.

If you could have the best quality with all the features Hyde provides at a similar price of a lower quality boat, why not row a Hyde? And, you’d get an easier rowing boat to boot!

The bitterness of poor quality lingers long after the sweetness of a cheap price.

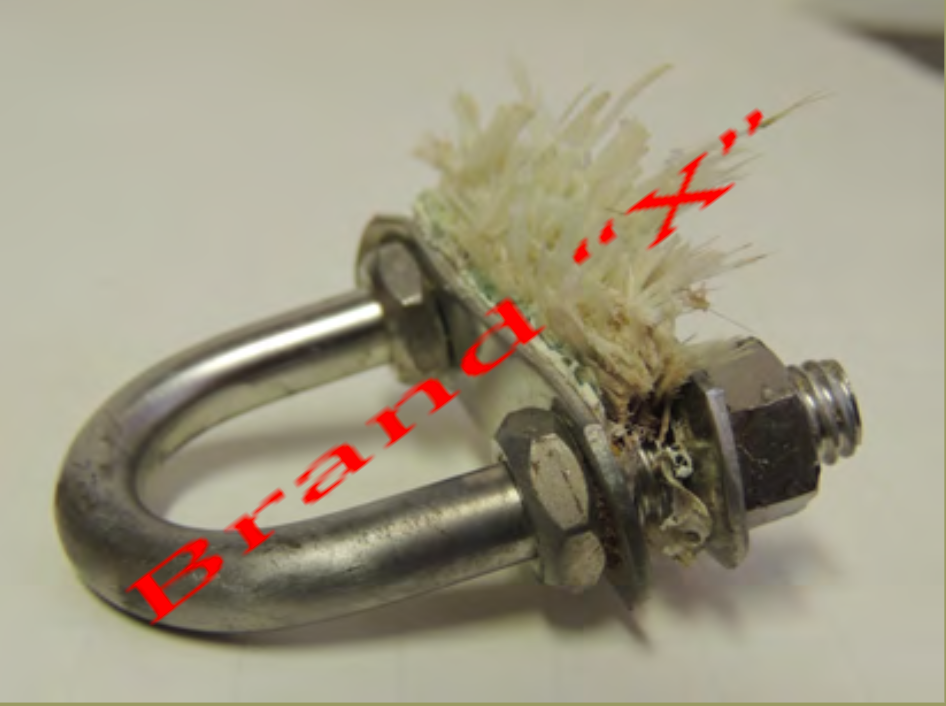

This is the bow eye from a “Brand X” boat. It has completely detached from the boat due to cheap manufacturing. At Hyde, quality is our goal. Don’t let poor craftsmanship keep you off the water!

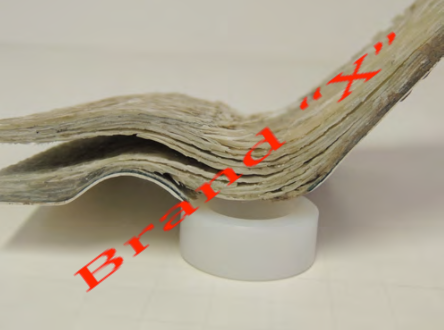

This is a cross section taken from the hull of a boat from another company. You can see that each layer has delaminated. This is due to rock impact and flexing. This clearly shows the need for quality materials and workmanship!

This fiberglass boat is a few years old. Ortho resin was used to make this boat. You can see how it deteriorates. Below you were learn why Isophalic (iso) resins are better, and why we use that exclusively.

Fiberglass Boat Construction

The first layer in our fiberglass boats is the gel coat. It is in this coat that the colors of the boat are added. We can make any combination of colors you’d like. After the gel coat comes the layers of fiberglass. We have found, through independent testing, the strongest and longest lasting combination of

fiberglass composite.

Even if you use high quality materials, if not done in the correct way, the layers will delaminate due to unavoidable rock impacts and flexing of the boat. We are continually sending our fiberglass professionals to classes so they are always up to date on all the new products and processes in the fiberglass industry. When you buy a Hyde, you are getting state of the art materials, assembled by knowledgeable craftsmen.

Resin

Have you ever run your hand along the outside of an old fiberglass boat? If you have, you might notice a white powder coming off the boat. This is due to a deterioration of the resin they’ve used. All fiberglass materials are constructed by saturating fiberglass with resin, therefore the resin is extremely important.

Orthophthalic resins are used to give the fiberglass structure. Orthophthalic (ortho) resins have a type of molecular structure that is considered to be the standard in the industry. These resins are cheap and quickly degrade. When they deteriorate, the performance and structure of the boat is compromised. This is what other companies use because most buyers aren’t aware of the difference in quality, and, when they’re new, there is little visual difference between Ortho and Iso resins. But even from the start, Iso resins will be glossier and look better; giving you a boat to be proud of for years to come.

We only use Isophthalic resin in our boats. Isophalic (iso) resins are much higher grade than ortho resins because the molecular structure is denser. These resins exhibit higher strength, greater flexibility, and are more waterproof than orthophthalic resins. You almost have to be a chemist to understand it, but the result is a boat that will last longer, be stronger, and look better over the years. Retaining that “like new” finish will add value to your boat. This resin will keep your boat in show room condition season after season

The most important part to remember about Isophthalic resin is that we are the only drift boat manufacturer to use it! This gives you a more valuable boat for similar pricing.

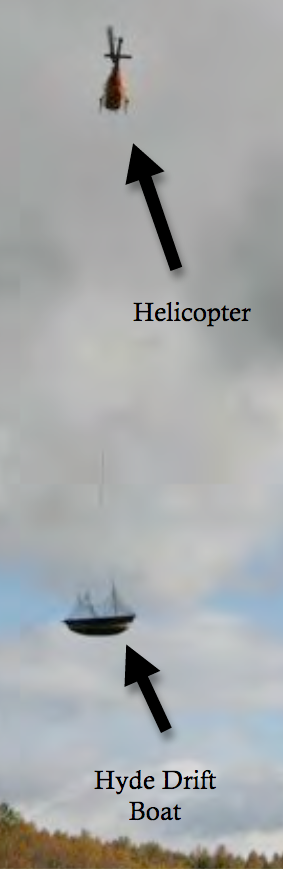

Hyde Boats are so rugged they are trusted in some of the most remote areas on earth! Sometimes the only way to access these locations is by flying.

Level Floors

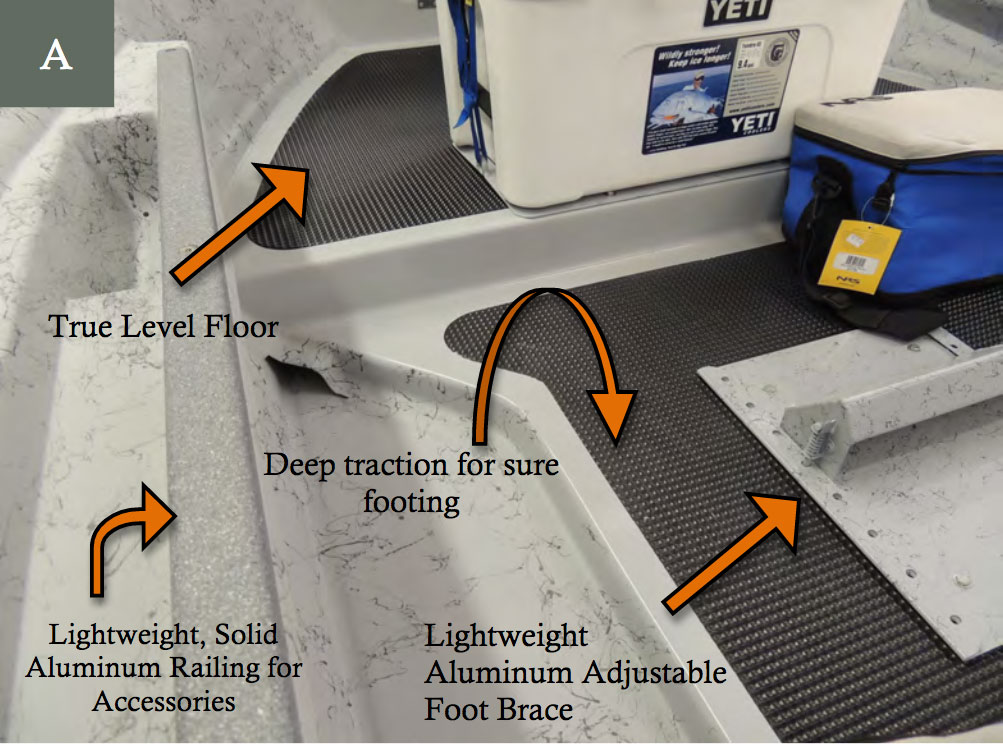

Our boats are constructed with true level floors. The deep textured surface is built right into the fiberglass, so you’ll have durable traction in your boat forever. These level floors allow for greater comfort and safety for the rower and anglers. You can imagine that it would be much more comfortable to stand on a flat surface rather than a slope all day. This also allows you to have greater stability when rowing or fishing.

- You can see the Hyde exclusive built in traction on the surface of the sub floor in this fiberglass boat.

- Level floors aren’t exclusive to just our fiberglass boats, our aluminum boats have durable, level fiberglass floors as well.

- This is a cross section cut from our subfloor. You can see the layers here ending with the aluminum plate.

Our sub floors are made up of 5 layers (some models differ slightly):

- The top layer is the textured gel coat. This is what you see on the surface. The floor is textured for superior traction.

- Just under the gel coat are two layers of hand laid bidirectional fiber glass cloth.

- The fiberglass is adhered to a ½-inch thick sheet of Nidacore. Because of its unique honeycomb structural integrity properties, Nidacore has an unparalleled ability to handle all kinds of stresses.

- After the sheet of Nidacore is a 1/8-inch thick aluminum plate. This is gives our subfloors secondary strength for solid accessory installation.

- Under the aluminum is more fiberglass (not shown in image). This holds everything in place.

The result is a Hyde exclusive level floor that is extremely light and durable.

Our Hull Design

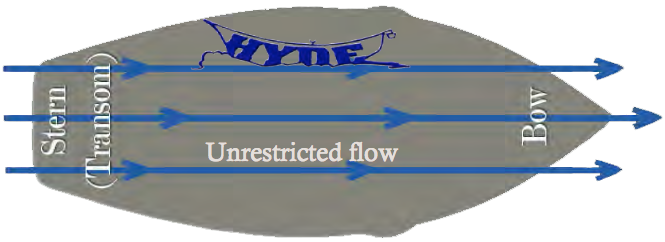

Have you ever seen dimples on an airplane wing? Of course not! Any imperfection on the surface of that plane would cause turbulence therefore compromising the performance of the aircraft to potentially impossible flight conditions. We know water and air are different, but they have similar characteristics.

We’ve taken our knowledge of aerodynamics and hydrodynamics, as well as the results from our testing, to give you the most innovative hull ever assembled. We’ve carefully designed and tested every aspect of these boats to ensure they are the best you’ve ever rowed.

We have had many engineers at different colleges test the hydrodynamics of our boats, ensuring the greatest performance in areas such as tracking, holding in fast water, and safety in various river conditions. We also test our designs to ensure that we deliver the best creature comfort possible.

The results of our testing and conclusions drawn by many fluid engineers show that the smoother the bottom, the less friction and drag the boat has

with the water. Because of this, you will not see any bumps, channels, or ridges on the bottom of our drift boats. Some of our competition’s boats are full of them. Solid engineering shows any channels or pocks on the bottom of the boat will cause turbulence and inconsistent flow. The resulting boat would be more difficult to row and more difficult to hold on track.

The hull of a Hyde Drift Boat is specifically designed to allow water to flow beneath it with the least drag possible. This means you’ll spend less time rowing, and more time fishing!

This is an image of a recess on the bottom of a “brand X” boat. Any imperfection causes drag, and drag means you’ll be floating down the river faster than you want to go in a boat that will be harder to row.

This is an image of a recess on the bottom of a “brand X” boat. Any imperfection causes drag, and drag means you’ll be floating down the river faster than you want to go in a boat that will be harder to row. This is the result of a flexible bottom.

This is the result of a flexible bottom.Brand “X” Bottoms

This is the bottom of a boat built by another company. You can see the pocks and channels recessed into the fiberglass. Engineering analysis shows that any imperfections or flexing (oil canning) of the bottom of the boat causes water turbulence and inconsistent water flow, which causes drag and makes the boat harder to row. Also, a flexible bottom will cause turbulence. The boat will be hard to row and wear out quickly. As it flexes, it fatigues the fiberglass fibers and rapidly wears out. After all, it is GLASS. Other boat companies build these floors because they are cheap to manufacture.

Pocks and channels cause turbulence.

Pocks and channels cause turbulence.Extreme Protection

Sometimes in extreme conditions, you may need some extra protection. We’ve developed a plastic shoe that fits perfectly with the bottom of your boat. When paired with our already rugged fiberglass or aluminum hulls, these “shoes” ensure that the bottom of your boat stays as smooth as the day you bought it. Offering almost friction free rowing river mile after river mile.

Chopped vs. Hand Laid Fiberglass

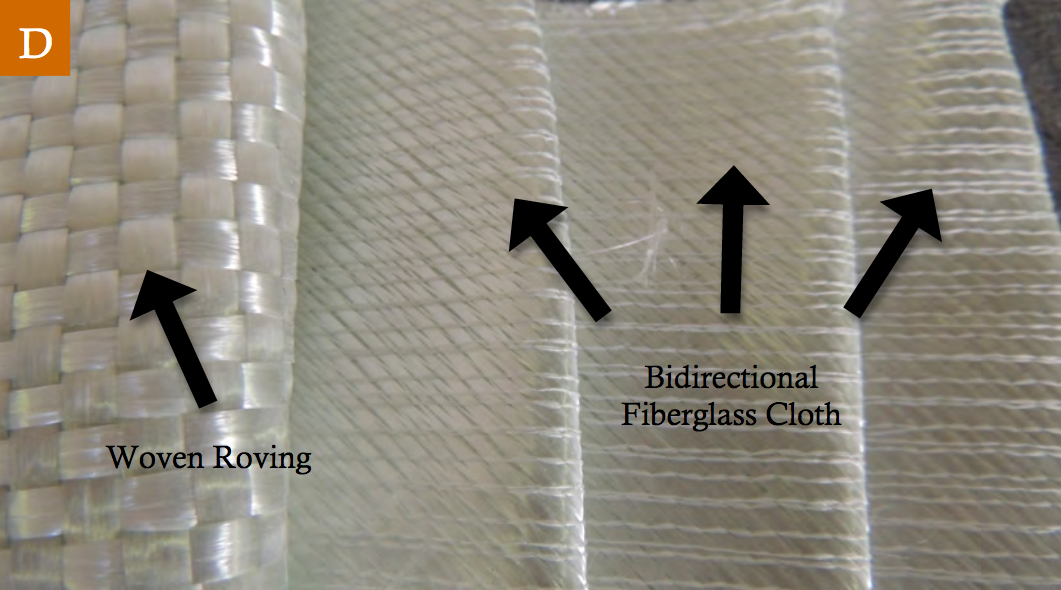

A few companies claim their boats are hand laid, however it is only the outermost layer of fiberglass that’s hand laid, the rest of the boat is the result of a chop gun. We don’t even own a chop gun! A chop gun is a device that uses compressed air to blow pieces of fiberglass and resin into a mold. The result is a boat with inconsistent thickness that is weaker, and heavier than a hand laid boat. All Hyde fiberglass drift boats are hand laid. Every layer of

multidirectional fiberglass is meticulously placed by hand; consequently, the boat is much stronger because the thickness of the hull is consistent.

Its like comparing particle board to plywood. Obviously plywood is much stronger than particleboard. The same theory goes for Hyde Drift Boats. We use hand laid fiberglass sheets saturated with Iso resin to give us the best hull on the market.

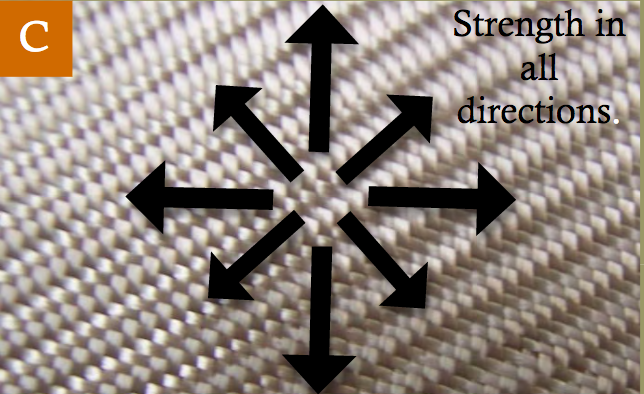

We use bidirectional fiberglass fabric to give our hulls multidirectional strength. The only way to make a hull with a chop gun as strong as one that has been hand laid is by making it much thicker and as much as 120 pounds heavier! That’s like having an extra passenger in the boat!

Chop gun fiberglass construction works great for shower enclosures, but you’re not rowing down the river in a bathtub are you?

It is much less expensive to build a boat with a chop gun because the fiberglass builds up much more quickly. That means less labor cost for the manufacturer. This lower quality of construction isn’t immediately visible to most buyers, consequently, that’s the method all of our competition uses.

A) This is an image of chopped glass before it is saturated with resin.

A) This is an image of chopped glass before it is saturated with resin. B) This picture shows chop glass being blown onto a mold.

B) This picture shows chop glass being blown onto a mold. C) We use bidirectional fiberglass because of its multidirectional strength. Bidirectional is up to 166X stronger than chop glass!

C) We use bidirectional fiberglass because of its multidirectional strength. Bidirectional is up to 166X stronger than chop glass! D) These are the layers of a Hyde drift boat. There are 3 layers of bidirectional cloth followed by a layer of woven roving that we use as a finishing layer. Not shown is the matting used between layers.

D) These are the layers of a Hyde drift boat. There are 3 layers of bidirectional cloth followed by a layer of woven roving that we use as a finishing layer. Not shown is the matting used between layers.BUYER BEWARE: some companies claim their hulls are hand laid when in fact it is only the outermost layer that is hand laid. Don’t be fooled by the chop gun sandwich!

Hand Laid Fiberglass

Each and every Hyde drift boat and fiberglass accessory is carefully hand made by world-class fiberglass craftsmen. We take pride in the lightweight strength this method gives our boats. You wont find a stronger fiberglass hull on the market.

For an added measure of strength, we’ve added extra layers of fiberglass in the chines of every boat. The chines are the bottom edge of the boat. This is

the area most likely to collide with rocks in the river, so we made ours stronger than any others out there! Others simply spray their boats into a mold, but this the last place you’d want to compromise on quality. In a Hyde Drift Boat, you can rest assured that you’ve got the strongest, lightweight hull on the market.